Development of the Blue Industry with 55 Years of Tradition

| Company | Blue Industrial Development Co., Ltd. | Foundation | July 18. 1970 |

| CEO | Hyeok-Beom, Gwon | Capital Fund | 29.6 billion |

| Product | Manufacturing of paper and lina paper for branch offices | The number of persons | around 100 persons |

| The total sales | 881million(2024.01.01~2024.12.31) | ||

| Office |

Headquarters (Factory) 9 Seotan-ro, Jinwi-myeon, Pyeongtaek-si, Gyeonggi-do

Youngpoong Package (20 Incha-si-dong-ro, Gadeok-myeon, Sangdang-gu, Cheongju-si, Chungcheongbuk-do), |

||

| Machines | PM #2 core board, 235ton/day PM #3 core board, liner board, 400ton/day |

||

| Equipment | Multi Cylinder mold type (PM #2), Multi Wire mold type (PM #3) | ||

| Etc | July 3, 1996 Stock Exchange Listing 1998. 5. 22 KS A 9002 1995/ISO 900 : 1994 Acquired Quality System Certification |

||

| Company | Blue Industrial Development Co., Ltd | ||

| Foundation | July 18. 1970 | ||

| CEO | Hyeok-Beom, Gwon | ||

| Capital stock | 29.6 billion | ||

| The number of persons | around 100 persons | ||

| Product | Manufacturing of paper and lina paper for branch offices | ||

| The total sales | 88.1 billion (2024.01.01~2024.12.31) | ||

| Office | Headquarters (Factory) 9 Seotan-ro, Jinwi-myeon, Pyeongtaek-si, Gyeonggi-do T. 031.660.8200 / F : 031.668.2655 Youngpoong Package (20 Incha-si-dong-ro, Gadeok-myeon, Sangdang-gu, Cheongju-si, Chungcheongbuk-do) T. 043.286.1610~3 / F : 043.286.1600(1614) |

||

| Machines | PM #2 core board, 235ton/day PM #3 core board, liner board, 400ton/day |

||

| Equipment | Multi Cylinder mold type (PM #2), Multi Wire mold type (PM #3) | ||

| Etc | July 3, 1996 Stock Exchange Listing 1998. 5. 22 KS A 9002 1995/ISO 900 : 1994 Acquired Quality System Certification |

||

Company history

| Core Board |

Paper used in manufacturing of paper core and paper tube

| Paper Type | Basis weight (g/m2) | Paper Feature | Usage |

|---|---|---|---|

| CB-SH | 400 | thickness, ring Crush, ply bond, tensile strength |

high strength core for fiber, film |

| CB-B | 400 | thickness, ring Crush, ply bond, tensile strength |

core for fiber, film |

| CB-CA | 250, 340, 400, 500 |

thickness, ring Crush, ply bond, tensile strength |

core for fiber(POY), film, paper, fiber drum, sleeve |

| CB-CB | 250, 340, 400 |

thickness, ring Crush, ply bond, tensile strength |

core for fiber(POY), film, paper, fiber drum, sleeve |

| CB-CC | 400 | thickness, ring Crush, ply bond, tensile strength |

core for fiber(POY), film, paper, fiber drum, sleeve |

| CB-D | 250, 340, 400, 500 |

thickness,bursting strength | Core for fiber(DTY), general paper core |

| Liner Board |

Paper used in manufacturing of corrugated cardboard and corrugated box

| Paper Type | Basis weight(g/m2) | Paper Feature | Usage |

|---|---|---|---|

| KAY | 180, 210, 300, 400 |

Color, grammage, moisture, bursting strength |

top side of corrugated board and corrugated box |

| KAYH | 300 | thickness, Cobb sizing | laminating paper |

| SKP | 180, 210 | Color, grammage, moisture, bursting strength |

top side of corrugated board and box |

| KLB | 175, 225, 300, 400, 440 |

Color, grammage, moisture, bursting strength |

top side of corrugated board and box |

| K2 | 180, 200, 250 |

Color, grammage, moisture, bursting strength |

back or middle side of corrugated board and box |

| KAR(coated,water-repellent) | 220 | top side of corrugated board and box (farm-products) |

top side of corrugated board and box (farm-products) |

| KAR(uncoated) | 220, 235 | top side of corrugated board and box (farm-products) |

top side of corrugated board and box (farm-products) |

| YPK | 180 | Color, grammage, moisture, bursting strength |

corrugated medium paper |

| PM #2 |

multi cylinder mold type

| Division | PM #2 | Unit |

|---|---|---|

| product | Core board | |

| machine type | multi cylinder mold type | |

| gsm | 200 ~ 500 | g / m2 |

| maximum width | 3,300 | mm |

| machine speed | 200 | m / min |

| total output | 300 | Ton / Day |

| equipment supplier | DOMESTIC |

| PM #3 |

multi wire mold type

| Division | PM #3 | Unit |

|---|---|---|

| product | Core board, liner board | |

| machine type | multi wire mold type | |

| gsm | 150 ~ 400 | g / m2 |

| maximum width | 4,100 | mm |

| ,svjimr dprrf | 500 | m / min |

| total output | 500 | Ton / Day |

| equipment supplier | OVER MECCANICA |

| Air pollution control facilities |

We have been operating air pollution control facilities by 4 step equipments SNCR, SDR, BAG FILTER and Wet Scrubber. We also have made every effort reduction of plastic waste and prevention of air pollution through incinerating plastic waste at one hundred percent capacity of own incinerator.

| Division | Incinerator | Air pollution control faclilites |

|---|---|---|

| Type | STOKER TYPE | SNCR, SDR, BAG FILTER , WET SCRUBBER |

| CAPACITY | 3,900Kg/hr | 75,000m2/H |

| SIZE | 26,000W x 52,000L x 28,000H | 18,000W x 25,000L x 28,000H |

| REFERENCE | AUXILIARY FUEL-LNG | DIOXIN ABSORPTION(ACPOWDERSPRAY) |

| SYNTHETIC RESIN WASTE 100% SELF INCINERATION | ||

| Water pollution prevention facilities |

We have instituted optimal prevention facility by hollow fiber membrane filter process for mitigation of water pollutants, and we also have done our best to reduce Water pollutants through continuous investment and improvement such as upgrading of process and environmental management

Treatment process

Treatment facilities

| Division | biological treatment facilities | Chemical treatment facilities | |

|---|---|---|---|

| Form | Bio-Combinator | Membrane bio-reactor | Penton oxidation reactor |

| Capacity | 7,400 | 1,500 | 175 |

| SIZE | 22,000 o x 22,000H | 25,000 x 16,000 x 5,000 | 3,000 x 3,000 x 3,500 x 2지 / 3,000 x 3,000 x 2,500 x 5set |

| Other | Pure-oxygen activated sludge process | hollow fiber membrane filter process | |

Water purity Control

| Type | Waste water | Biological treatment water | Discharge water | Effluent quality standard |

|---|---|---|---|---|

| COD | 1,500 | 50 | 30 | 70 |

| BOD | 1,300 | 15 | 15 | 60 |

| SS | 2,000 | 10 | 10 | 60 |

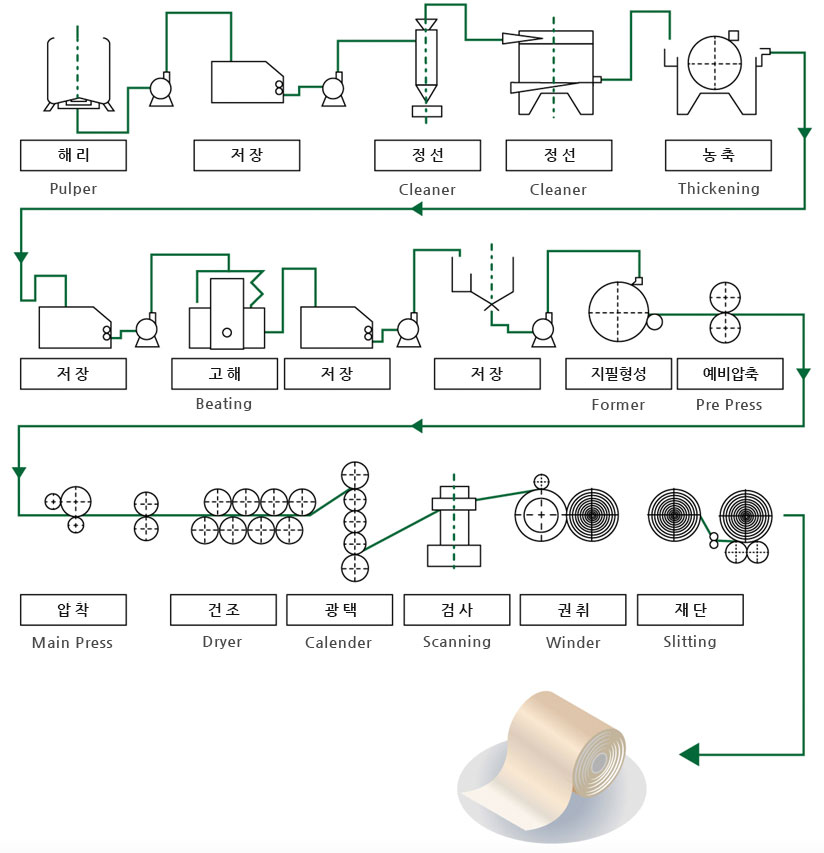

Production Process

"Global Leader of BLUE INDUSTRIAL DEVELOPMENT”

The talent image that will lead the blue development industry in the knowledge industry society of the 21st century is enterprising and challenging youth with globalized perspective, practical ability, specialized knowledge, information and ability.

1. Globalized people

People who have wide vision and international sense based on knowledge and understanding

of cultural difference.

2. Informatized people

People who creates intellectual value through informatization and have basic grounding as a citizen

of knowledge based society.

3. Creative people

People who develops themselves through self-innovation in creative way with critical mind.

4. Intellectual people

People who have a goal to become world’s best with professional mind.

5. Autonomous people with social responsibility

People who respect value and thought of the others and have strong sense of service to society

and organization.

PERSONNEL / WELFARE

Blue Industrial Development is making best effort to make working environment that each of member can show their abilities and talents through performance based fair evaluation

PROMOTION

egular promotion : Annual evaluation (Once a year)

Special promotion : If ncessary.

LIFE SUPPORT

In-house Employee Welfare Fund

Tuition support (Kids from middle school to college)

Money gift for congratulations and condolences of family events

House loan / Accommodations for employee

OTHERS

Continuous-service allowance (10y, 15y, 20y, 25y, 30y)

Annuity insurances / Free shuttle bus

Play fund

Head Office

9, Seotan-ro, Jinwi-myeon, Pyeongtaek-si,